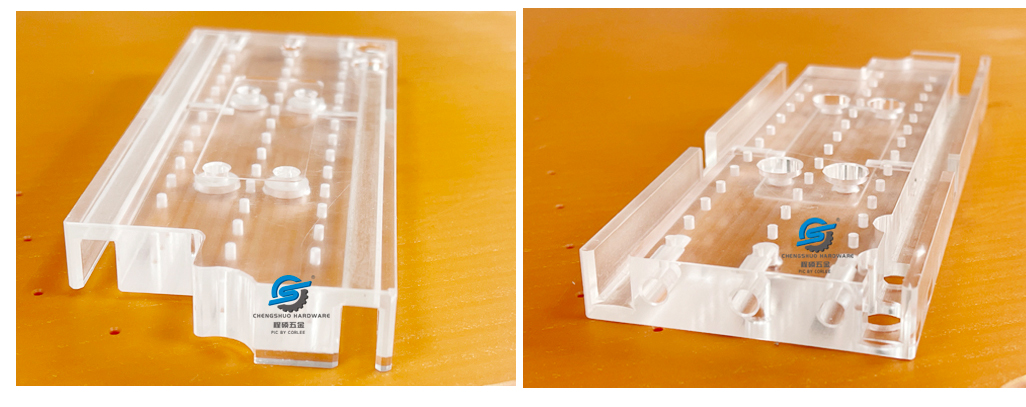

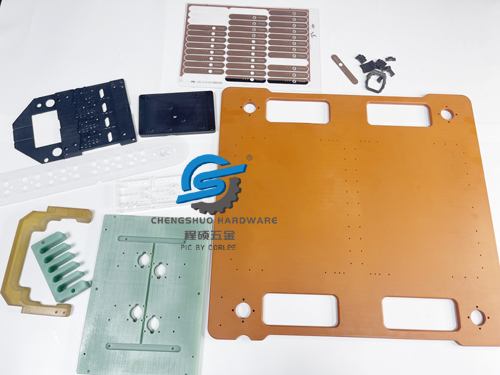

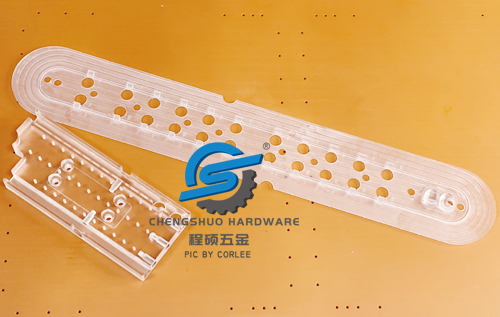

Imishini ye-CNC yemikhiqizo ye-acrylic ingafinyelela izakhiwo eziyinkimbinkimbi, inciphise ukuqhekeka kwezinto ze-acrylic ngesikhathiimishini, futhi ihlangabezane nezimfuneko zokunemba okuphezulu zemikhiqizo.

I-Polymethyl methacrylate (CH3│—[—CH2—C——]—│COOCH3) inezakhiwo ezinhle ezibanzi zemishini, ibalwa phakathi kwezihamba phambili kumapulasitiki ajwayelekile. Ukuqina kwayo, ukugoba, kanye namandla okucindezela aphakeme kune-polyolefin, futhi aphakeme kune-polystyrene, i-polyvinyl chloride, njll., kodwa ukuqina kwayo komthelela akulungile. Kodwa futhi ingcono kancane kune-polystyrene.izakhiwo zomzimba.

I-PMMA inamandla amakhulu okusebenza: isisindo samangqamuzana esihlobene se-PMMA singaba yizigidi ezi-2. I-polymer enamaketanga amade, futhi amaketango akha i-molecule athambile kakhulu. Ngakho-ke, i-PMMA inamandla amakhulu uma kuqhathaniswa futhi imelana nokwelula kanye nomthelela. Izikhathi ezi-7 kuya kwezingu-18 ziphakeme kunengilazi evamile.Kunohlobo lwengilazi ephilayo eshisiwe futhi yeluliwe, lapho izingxenye zamangqamuzana zihlelwe ngendlela ehlelekile kakhulu, okuthuthukisa kakhulu ukuqina kwento.

I-Acrylic ivame ukusetshenziswa embonini ukukhiqiza nokwenza amaphaneli wezinsimbi namakhava, futhi okokusebenza okuhlukahlukene okuhlinzayo kanye nezokwelapha, izinto zasendlini: izinsiza zokugezela, imisebenzi yezandla, izimonyo, abakaki, izindawo zokugcina amanzi, njll.

Lapho usebenzisa i-CNC ukucubungula imikhiqizo ye-acrylic, udinga ukunaka amaphuzu alandelayo:

1. CNCIdizayini yokuhlela ye-AcrylicUkwenza imishiniIyacubungula

Okwe-acrylic (I-Polymethyl methacrylate, i-PMMA), imininingwane yokuhlela yomkhiqizo kufanele yakhelwe ngokuya ngesimo somkhiqizo, njengesivinini sokuphakela kwamathuluzi kanye nesivinini sokuzungezisa ngesikhathiimishiniukucubungula. Ngokwesimo sangempela somkhiqizo, inqubo yokuhlela nokugeleza kufanele kuthuthukiswe ukuze kuncishiswe ukucekela phansi ngesikhathi sokucubungula.

Lapho usebenzisa i-CNCimishiniacrylic, kubaluleke kakhulu ukusetha izinga elilungile lokuphakelayo. Uma izinga lokuphakelayo lishesha kakhulu, i-PMMA ingase yephuke ngenxa yokucindezela okukhulu kokusika. Amazinga okuphakela ngokushesha angabangela izingxenye ukuthi ziphume endaweni yokusebenza noma zishiye ukungapheleli engxenyeni; Izinga lokudla okunensayo lingaphinda likhiqize izingxenye ezingalungile ezinezindawo ezimahhadlahhadla, ezingaqediwe.

2. Ukukhethwa Kwamathuluzi Ekucubunguleni I-Acrylic Kumele Kufaneleke

Ukucubungula amashidi e-acrylic kudinga ukusetshenziswa kwamathuluzi afanelekile. Ngokuya ngokuma kwethuluzi, amathuluzi asetshenziswa ngokuvamile ahlanganisa izigayo zokugcina, izinqamuli zekhala zebhola, ama-flat cutters, njll. I-flat cutter ifaneleka ukusika nokuhlanza izindawo ezinkulu, isigayo sokugcina sisesimweni se-engeli efanele futhi kufanelekile. ukuze kucutshungulwe imiphetho yombhalo kanye nemifanekiso, futhi i-ball nose cutter isesimweni se-arc futhi ifanele ukucubungula amaphethini namajika anembe kakhulu.

Izinto zommese nazo zibalulekile. Isibonelo, i-high-speed steel isika i-acrylic, kodwa ayihlinzeki ngokuqeda okuhle kwendawo. Amathuluzi edayimane angathuthukisa isiphetho esingaphezulu kodwa abiza kakhulu. I-Carbide imvamisa iyimpahla yokuzikhethela ye-CNC yokusika i-acrylic.

Okwe-CNC machining acrylic, kuyanconywa futhi ukuthi usebenzise i-engela enqenqemeni yeraki engu-5 degrees kanye ne-engeli eyengeziwe engu-2 degrees.

Ngaphezu kwethuluzi lokusika, kufanele futhi unake ukujula kokusika, isivinini, njll. lapho ucubungula imikhiqizo ye-acrylic ukuze uqiniseke ukuthi ukwakheka kwe-acrylic impahla eluhlaza akonakali. I-Acrylic ngokuvamile iyimpahla ebuthakathaka. Ngesikhathi sokusika kwe-CNC, ukusebenzisa amathuluzi afanele kanye nokujula okufanelekile kokusika nesivinini kungagwema ukucubungula izinsalela ezibangelwa ukuqhekeka noma ukushelela. Ekusikeni okuqhubekayo, kuyadingeka ukubamba ijubane langempela lokucubungula nokujula kwethuluzi, futhi uzame ukuqinisekisa ukuthi isakhiwo sezinto ezibonakalayo asonakaliswa, njengokuhlukana, ukunqanyulwa, njll Ngesikhathi esifanayo, ukunakwa kufanele kukhokhwe ekunciphiseni ukushisa kanye nogesi omile ngesikhathi sokucubungula.

3. Sebenzisa I-Correct Drill Bit And Bevel

Qinisekaii-drill ingakha ngempumelelo izimbobo ku-acrylic ngokukhetha into efanele yokubhoboza. I-Carbide iyisinqumo esihle kakhulu sokumba i-acrylic, futhi abakhiqizi abaningi basebenzisa ama-O-groove end mill drill bits aklanyelwe ukusika nokubhola i-acrylic. Ukwengeza, ama-drill bits adinga ukugcinwa ebukhali, ama-drill bits azokhiqiza amaphethelo angahlanzekile futhi angaholela kalula ekuqhekekeni kwengcindezi nokuqhekeka.

Lapho CNC machining acrylic, kungcono ukusebenzisa bevel nge drill bit. Ukuze uvimbele i-drill bit ekulimazeni izingxenye ze-acrylic material, idinga ukutshekiswa phansi ngothambeka olubushelelezi ukuze kuvinjwe umonakalo futhi kuqinisekiswe indawo ebushelelezi.

Ngesikhathi esifanayo, ukujula nokusika kufanele kuqashelwe. Indlela yokuzungezisa yethuluzi le-CNC: kwesokunxele nakwesokudla, noma ngokuphambene newashi nangokuhamba kwewashi, kufanele ivumelane ngokunengqondo nomkhiqizo ukuze kuqinisekiswe ukunemba kokusetshenziswa komkhiqizo nemisebenzi yokuklama.

Isikhathi sokuthumela: Jan-16-2024