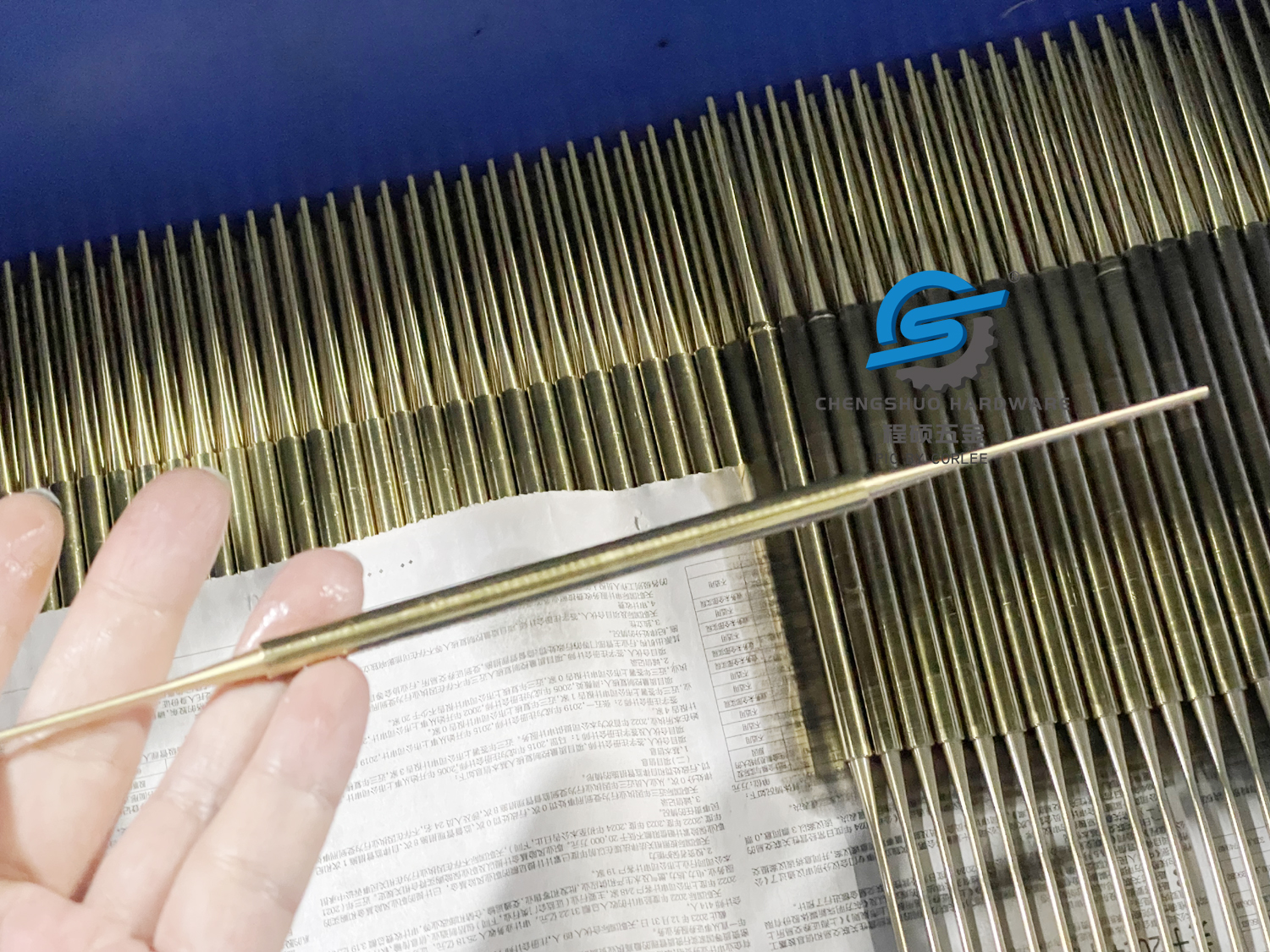

I-Brass Thimble Fixed Pin efakwe u-Chengshuo 5 ama-lathe athomathikhi amahlanu e-axis-Ngu-Corlee

NgokwezifisoI-Brass Thimble Fixed Pin Machining Factory CNC Milling TurningI-Chengshuo Hardware Machined

Ukubuka konke kwenqubo yokwenza imishini kusetshenziswa i-lathe ezenzakalelayo ye-axis emihlanu:

1. Ukusethwa: Lungiselela i-lathe ye-othomathikhi ye-athomathi emihlanu yemisebenzi yomshini, uqinisekise ukuthi isiqeshana sokusebenza namathuluzi okusika afakwe kahle futhi aqondaniswe.

2. Iyalayisha: Layisha insimbi yethusi ku-lathe, uqinisekise ukubamba okuqinile ukuze kuncishiswe ukudlidliza nokuqinisekisa ukunemba ngesikhathi somshini.

3. Ukuhlelwa kwendlela yamathuluzi: Thuthukisa uhlelo lwendlela yamathuluzi ukuze usebenzise umsebenzi wama-eksisi amahlanu ukuze umshini ngokuphumelelayo izici eziyinkimbinkimbi zephinikhodi yokukhipha i-brass ejector.

4. Ukuphenduka nokugaya: Sebenzisa i-lathe ye-axis emihlanu ukwenza imisebenzi yokujika neyokugaya ngeyunithi eyodwa, okuvumela amajiyometri ayinkimbinkimbi, ama-undercuts, nezinye izici eziyinkimbinkimbi ukuthi zenziwe ngomshini.

5. Ukushintsha ithuluzi: Sebenzisa ithuluzi elizenzakalelayo lokushintsha idivayisi ye-lathe ukushintsha phakathi kwamathuluzi ahlukene ngokuya ngezidingo zezinqubo ezihlukahlukene zokucubungula njengokujika, ukubhola, nokugaya.

6. Ukulawulwa kwekhwalithi: Izinyathelo zokulawula ikhwalithi ziyasetshenziswa phakathi nenqubo ukuze kuqinisekiswe ukuthi izikhonkwane ezigcina ithoni lethusi elifakwe ngomshini zihlangabezana nokubekezelelana okucacisiwe kwe-dimensional kanye nezidingo zokuqedwa kwendawo.

7. Ukuqedwa Kwendawo: Uma kunesidingo, yenza noma yimiphi imisebenzi yokuqedela indawo edingekayo njengokupholisha noma ukukhipha ukuze uthole ikhwalithi yendawo oyifunayo.

Ukusebenzisa i-lathe ye-othomathikhi ye-athomathikhi emihlanu emshinini wezikhonkwane zethusi zokukhipha kunenzuzo yokuguquguquka okuthuthukisiwe kanye nekhono lomshini wejiyometri eyinkimbinkimbi ngeyunithi eyodwa, ekugcineni kusize ukukhulisa ukusebenza kahle nokunemba.

Uma unezidingo ezithile zokuklama noma ukubekezelela izikhonkwane zakho ze-ejector zethusi, kubalulekile ukuqinisekisa ukuthi ukuhlelwa nokusethwa kwe-lathe yakho ezenzakalelayo ye-five-axis kwenziwa ngendlela oyifisayo ukuhlangabezana nalezo zici.

Kubalulekile ukuqaphela ukuthi ukusebenza kwemishini ethile kanye nemingcele yezikhonkwane zethusi ze-ejector zingahluka ngokuya ngedizayini ethile, ukubekezelelana kanye nezidingo zokuqeda phezulu. Ukwengeza, ukusebenzisa amathuluzi okusika afanele, isivinini somshini, kanye nokuphakelayo komshini wethusi kubalulekile ukuze uthole imiphumela yekhwalithi ephezulu.